Announcement posted by Couplemate Trailer Parts 08 Mar 2021

Couplemate Caravan Electric Brakes and Magnets made Simple

Caravan electric drum brakes, magnets and optimising electrical connection methods is a trendy topic.

Key points

Key points

- Check magnet arm for wear. Loose on magnet arm post.

- Pull the breakaway pin and measure the voltage at all magnets

- If less than 12v recharge breakaway or upsize cabling to magnets.

- Check for magnet wear inside the drum. The surface should be smooth.

- Install offroad magnets if magnet arms are worn.

- Measure lanyard pulls pin when chains are fully stretched.

- Easier to replace the whole backing plate than replace parts.

- Dexter offroad electric brakes are now available.

You may be surprised, that even auto electricians get caravan and camper trailer electric brakes wrong at times.

If there is a problem with electric brake magnets, the answer is likely to be in the information below.

If you find a solution, please leave me a review comment below.

[caption id="attachment_45148" align="alignright" width="300"]

12-inch Offroad Electric Brake Magnet - Click the Image[/caption]

12-inch Offroad Electric Brake Magnet - Click the Image[/caption]How to identify an electric magnet

- Green cable leads identify a 10" electric magnet.

- White cable leads identify a 12" electric magnet.

Electric brakes are a legal requirement for all trailers over 2000kg ATM. Hydraulic disc brakes controlled by an electric brake controller are also acceptable.

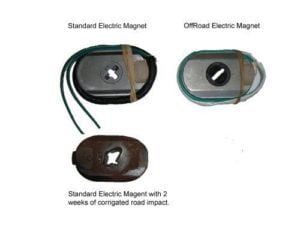

A centre cross in the middle of the magnet identifies a standard electric magnet.

This type of magnet has copper 3mm green leads. The 3mm refers to the copper cross-sectional area. A 3mm external cable is used to join the tiny copper inside the bobbin or casing of the magnet.

To reduce voltage drop on cable runs to your brakes, select 5mm cable if your cable run is less than 6 meters.

The gross trailer mass of your rig is the weight on the wheels when connected to your tow vehicle. Tandem axle brakes over 2000kg ATM require electrically activated brakes on both axles.

Cable Selection

When selecting cable to wire your Caravan braking system, you need 5mm when running cable approx 6 meters or if you are using an automotive type cable, use 10m or larger.

Check this and insert 6.4 amps for two magnets and 6 meters of cable. Click here for correct cable sizing.

Finally, do not wire across the axle as this method requires more copper and creates copper losses and therefore, more voltage loss. Wire the cable down inside each chassis rail. Drill a hole near the magnet tails then exit the frame rail, with the supply cable.

Alternatively, if cabling is wired across the axle, increase the size of this cable to reduce voltage loss. If not wired correctly, the magnet at the end of the line will not brake correctly.

Al-ko Off-road Caravan Magnet Upgrades

Al-ko Off-road Caravan Magnet Upgrades

Off-road magnets are essential when travelling on corrugated roads.

There is no retaining clip to hold magnets on to the magnet arm.

Al-ko recommends using a rubber band to temporarily retain the magnet into position until the 1st instance of braking releases the rubber band.

Consider a magnet upgrade before your trip to save you the expense of brake failure on your outback trip.

A few other spare parts like bearings, grease, white spirits to clean parts and a few extra wheel nuts are always handy spares.

Why dirt roads destroy standard electric magnets, click here.

[caption id="attachment_11037" align="alignright" width="300"]

Tekonsha Primus IQ Brake Controller - Click the image[/caption]

Tekonsha Primus IQ Brake Controller - Click the image[/caption]Caravan Electric Brake Controllers

Most brake controllers will not give full voltage when stationary. They provide zero power when stationary if the brake controller has a proportional braking feature.

Advanced proportional braked controllers such as the Tekonsha, use the trailers momentum or vehicle inertia to activate the trailers brake system..

A natural explanation may be to consider a pendulum inside the brake controller applies more voltage when the swing moves forward during braking.

When the vehicle is stationary, the voltage will be much less than 12v unless you have a dial resistor brake control unit. There can also be a time delay with some brake controllers.

The proportional control only works when your car is in motion and braking.

You may, of course, use manual control to activate your electric brakes. Pulling the pin on your breakaway switch will apply a brake force equal to full braking on your trailer's brake.

Critical information on how to adjust a Safety Switch Lanyard to the correct length.

[caption id="attachment_6340" align="alignright" width="300"]

Damaged Electric magnet caused by rough dirt roads.[/caption]

Damaged Electric magnet caused by rough dirt roads.[/caption]Electric Magnets explained:

- Standard magnet. Uses a clip to hold it into position and a spring to hold press the magnet square into the drum surface when braking.

- The Al-ko off-road magnet has a spring but no clip. A rubber band has wrapped the magnet to keep it in place during assembly. The rubber band disintegrates upon the first application of the brakes.

- After two weeks on corrugated roads, a new magnet will require replacement. Vibrations have caused the metal tip of the magnet arm to slowing cut through the electric magnet. At this stage, the copper wire on the bobbin has been rendering the magnet non-functional. Now you can see an excellent reason to put off-road magnets on your rig.

Caravans electric magnets draw 3.2 amps @ 12v each

(a) The big mistake when wiring electric brake magnets, is to wire 3mm cable down one side then run more wire across the axle to the other magnet and connect.

Even manufacturers continue to make this mistake.

The long, additional run of the cable causes more voltage loss than is necessary.

(b) The correct method using 6mm cable or larger is to run a wire down EACH chassis rail and connect each magnet independently. This type of connection reduces copper losses and the resulting voltage loss.

(c) Proportional controlled electric brake controllers are most common in today's market. The easiest way to explain proportional control is to think of a pendulum.

When your car is moving forward, the pendulum moves backward and forwards according to the inertia of your vehicle. The more braking you apply (pendulum moving forward), the more current is supplied to your brakes.

Confused want the correct cable size?

You will need the following

- Distance from your car battery to your electric magnets.

- Amps per magnet.

- 6.4A @ 12v per side gives you around 6mm cable per side.

- If you run across the axle, then the equation is 12.8a @ 12v gives you 12mm cable

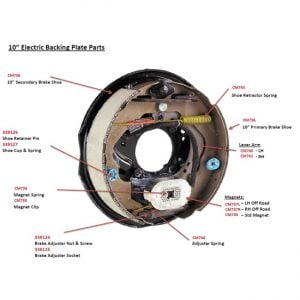

10-inch Electric Brake Standard Assembly incl Park. Click to purchase[/caption]

10-inch Electric Brake Standard Assembly incl Park. Click to purchase[/caption]My recommendation is to run 2 x 6mm or 10B&S down each chassis rail for the best braking.

Then click here. This website will calculate the correct size cable for you.

If you think that was good, please go to the bottom of this page and give us a rating, please.

Alternatively, contact steve.wotherspoon@couplemate.com.au if you require clarification.

I have a Master Craftsman electrical certificate issued by the NSW Electricity Commission.

TIP: Having problems replacing magnets or brake shoes? Replace the whole electric backing plate for $93.67. Click the image on the right and buy.

Caravan Electric Magnets Not Working?

It is not unusual for your caravan electric brakes NOT TO WORK when stationary. Proportional brake controllers supply zero voltage whilst stationary. Activate the brakes manually when stationary.

Quite often I will get a call about uneven braking, or one brake is stronger than the other backing plate.

Wiring magnets in series and using an undersize cable is the cause of the problem.

Wiring electric magnets with cable size of 6mm for the single axle (2 magnets) and 5mm for tandem axles. (4 magnets)

A voltage drop occurs when an insufficient cross-sectional area of copper that causes the voltage problem of uneven braking.

Why is it so, I asked my Technical College Teacher

His reply was, "Voltage loss in the cable is inversely proportional to the size of the copper."

I.e. the more copper, the less the energy loss.

If you are having problems with your brakes, then it is most likely to be a cable problem.

Wire your brakes in parallel, not in series.

Connecting electric magnets directly to your tail light will cause severe voltage losses.

Can my electric brakes stop caravan sway?

Yes, new technology can eliminate caravan sway. Visit this article to learn how to stop caravan sway.

Drum Brakes still not working?

Here is a little-known cause of electric brake failure called magnetic induction in your drums from constant use and magnet scraping on the metal surface.

Here is a little-known cause of electric brake failure called magnetic induction in your drums from constant use and magnet scraping on the metal surface.

You drums could be magnetised repelling your magnets thus causing ineffective braking.

If your magnets are drawing less than 3.2A each, there are two reasons

- Short circuit in your magnet

- Your magnet is being repelled by the drum.

- The solution for this is reversing the wires on the back of the backing plate.

Love to hear your comment if this solution fixes your problem.

Caravan Electric Brakes Tips:

- Adjust caravan electric brakes, so the wheel spins between 1/2 and one turn.

- Brake shoes may be re-adjustment after the first 200km.

- Use a good brand electric backing plate. Not all backing plates are the same.

- Chinese bearings are often the cause of overheating brakes. Overheated brakes create a lot of dust inside your drum.

- Check out the price for replacing both backing plates as opposed to magnets and shoes. You could save a whole lot of pain by replacing the entire backing plate. Just a small tip many folks overlook.

- 12" electric magnets have a white coloured cable exiting the magnet body.

- Ensure to check your lanyard cable on the breakaway switch is the right length.

- Last tip, not all backing plates are the same. Al-ko and Couplemate make good backing plates you can trust and I yes, I am a little bias towards Couplemate.

[caption id="attachment_5304" align="alignright" width="200"]

12" Electric Brakes[/caption]

12" Electric Brakes[/caption]Mechanical Problems can also develop with caravan electric brakes.

- Loose magnet arm causes uneven wear on the magnet and loss of braking power.

- Shoes not aligned correctly generate heat.

- Uneven adjustment on the left and right shoes causes loss of braking power.

- Bearings are a significant cause of overheating. Chinese bearings may be the problem. Quality bearings have the words Japan written on both the cup and race.

- Here is a rare fault that causes ineffective braking. Constant use of drum brakes can cause the drum to become magnetised.

- Simply replacing the drum can fix this also try and transpose the connecting cables.

Alko Off-road electric brake adjustment guide.

"Electric Brakes made Simple" is another electrical article by Steve Wotherspoon.

Finally, if you found this information helpful, please leave a review below.

* Life Time Guarantee on all Couplemate manufactured products provided those products are found to have been used according to the manufacturer's product recommendations on our Terms and Conditions Page. If the product you purchased cannot be located on our trailer parts store, then the product is not manufactured by Couplemate Trailer Parts Pty Ltd and is not covered by Couplemate's Life Time Guarantee.

© Steve Wotherspoon 24th March 2014